High Vacuum Technology

High Vacuum Technology is used in many market segments, but especially also in the Research and manufacturing of smart optics, reactive coatings, space, and nano technology.

Our goal is to provide the best possible, – as well as the safest equipment for vacuum applications used in research and development of fusion technology. Specially the handling of Hydrogen isotopes, which is our field of action. Here we tuned existing technology, added new features, or developed entirely new tools for the tasks at hand.

All to provide our customers with exactly what the need. We are also capable to manufacture series of bespoke parts in timely manner.

The difference

We designed our products specifically for handling of Tritium or other precious and or dangerous gases/ liquids, building on our decades of practical Tritium gas-handling. We optimize all our products to fit the following key aspects:

Safety/ Material/ Operation/ Lifespan

What we offer

Smolsys provides tritium compatible High Vacuum and gas handling valves/components in

Compatible to most «face seal» components of other brands, such as VCR®

Plan your handling system

High Vacuum Components

Valves & Actuators

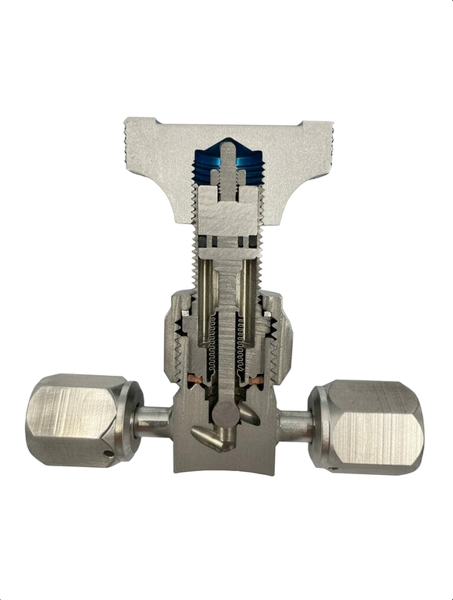

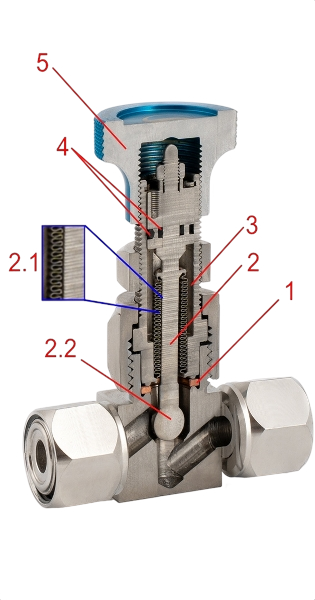

Picture: Cut open valve showing the additional seals

The actuators in their very compact built can be plugged to the valve without the need of removing it. They again are tested to withstand one million cycles.

Valve Dual Seal Technology

Our valves consist of valve base and a screwed valve body (upper part), connected by a copper seal (1)

Besides the copper seal*, all valve parts are made from high-grade stainless steel.

The stem (2) contains a metal bellow (2.1) that allows the sphere (smolball) (2.2) to close the valve, by pressing into the valve seat.

This metal bellow is very durable, but a part that is elastically deformed by the valves open-close operation.

Even the valves are tested to withstand very high opening-closing cycles, it is possible, that the metal bellow, being the weakest part of the valve, can break at some point. This would result in a leak between the stem and the hand wheel (3), where atmospheric pressure may flow in, or compressed gas may escape the valve.

This unlikely, but potentially severe occurance is addressed in our valves by a set of O-rings (4) that seal the valve stem towards the hand wheel (5).

Tests have shown that these additional seals are capable of keeping the vacuum tight, even when an unlikely break of the main barrier, the metal bellow should occur.

Tritium could be likely monitored on a low level, allowing to determine a broken bellow.

*Stainless steel seal or welded valves on request

Dual Sensored Pneumatic Actuators

Our pneumatic actuators (1) for the High Vacuum Valves (2) which allow for an automated valve opening/closing, are (against the market standard) dual controlled by sensors (2).

The open and the closed position of the valve are surveilled, allowing for an exact confirmation of the valves position:

Open/ closed or «undefined». The undefined position feedback show up in case of a not fully closed or opened valve, e.g insufficient compressed air pressure or blockage of the valve seat/ stem. It provides an additional safety feature in tritium handling systems.

ATEX Sensors for application in an explosive environment are optionally available.

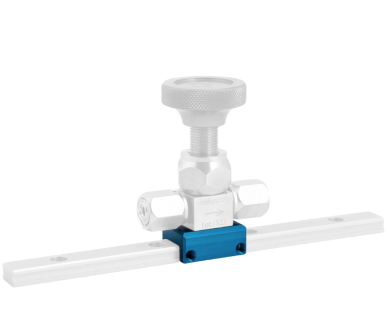

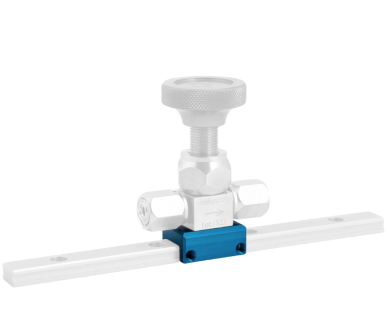

Rail Block Mouting system

From experience working with face sealed valves, we know, that exchanging them in a system of multiple components with adjacent valves, is a difficult task, – especially when they are traditionally screwed onto a backplate.

A n exchange in such a case means the disassembly of many connected components, which is in terms of work and contamination risk not favorable. Potential leaks can occur with every unnecessary disassembly/ re-assembly of a gas tight vacuum systems.

Using our Rail/Block Mounting System, the valves and components can remain connected and be slid as a whole group, allowing fast and easy exchange of components.

Valve Lock system

Some manual valves need to remain open or closed for process or safety reasons. We have integrated a ratchet system into the hand wheel, that allows the engagement of the wheel only, after it is unlocked. With high vacuum metal bellow valves (doe to their short travel of the stem for opening/closing), traditional padlock handwheel locking methods are not suitable.

For more information

For more information, please don’t hesitate to contact us. We’re here to assist with any questions or provide additional details to help you make informed decisions. Reach out today, and let’s connect!

For more information

For more information, please don’t hesitate to contact us. We’re here to assist with any questions or provide additional details to help you make informed decisions. Reach out today, and let’s connect!